OVHcloud, the European cloud leader, celebrates this month 20 years of innovation in the data centre thanks to its proprietary liquid-cooled servers.

Operating 34 data centres globally with over 450 000 servers, OVHcloud has long been pioneering a sustainable approach where cooling has been designed in-house for energy-efficient data centres that contribute to preserving the environment.

Pioneering watercooling in the data centre

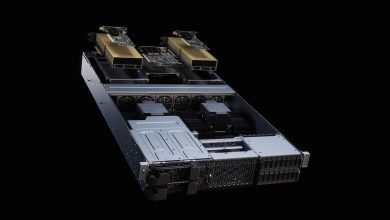

Ever since 2003, OVHcloud has been developing, using and refining a liquid-cooled system to dissipate waste heat emitted by power-hungry components in servers, namely processors (CPU and GPU). From the pumping substation to the water blocks in direct contact with chips, heat finds its way back outside of the data centre and is transported by water for final dissipation through optimized dry coolers. Taking advantage of the reduced thermal resistance of water than that of air cooling, and without the use of any kind of refrigeration method, OVHcloud consistently fine-tuned its cooling techniques to reach industry-leading levels of power usage effectiveness (PUE) and water usage effectiveness (WUE) per data centre.

Continuously innovating for best-in-class industry indexes

Accompanying the latest trends in chipmaking, OVHcloud’s water-cooling techniques are efficiently cooling modern processors with high thermal envelopes (TDP). Constantly looking for improvements, OVHcloud adopted a Delta T = 20K for its most recent data centres [1]. Designating the temperature difference between water coming in and out of the data centre, this parameter is crucial to water efficiency leading to the Group’s water usage effectiveness (WUE) ratio that is below 0.2l/kWh. This represents the equivalent of a glass of water used to cool down a server during 10 hours of use. While the cloud industry average WUE reaches 1,8l/kWh [2], OVHcloud stands out thanks to its innovations that also benefit the Group’s average PUE of 1.28, lower than the 1.55 [3] industry average according to 2022 estimates. These water usage efficiencies and power usage efficiency indexes, pave the way for compliance with future certifications.

An industrial model servicing circular economy principles

At the heart of 20 years of innovation to build a sustainable cloud are OVHcloud’s factories, located in Croix, France, and Beauharnois, Canada. They give OVHcloud total control of the design and production of its servers with significant advantages in terms of innovation, competitiveness, and resilience. This vertically integrated model is part of a short, circular manufacturing circuit where 100% of the servers are dismantled after use and provided through extensive testing, components for reuse and therefore contribute to the extension of the overall lifecycle of the hardware. This guarantees OVHcloud’s servers to operate for at least 5 years. OVHcloud also applies its circular approach to the site of the data centres, rehabilitating existing buildings rather than building new ones.

Customers directly benefit from these extended components and the building’s lifespan, as it optimizes their own carbon footprint.

Allowing ambitious sustainability commitments

By pioneering innovation in eco-friendly cooling systems, the Group has already made the following commitments:

- Target of 100% low-carbon energy sources by 2025,

- Contribution to Global Net-Zero for scopes 1 and 2 by 2025,

- Contribution to Global Net-Zero on full scope by 2030,

- Zero waste to landfill by 2025 (at constant geographic scope and including waste from OVHcloud processes)

In the coming weeks, OVHcloud will implement a carbon calculator accessible directly from its platform to give customers an understanding of their actual cloud carbon IT footprint, demonstrating once more that sustainability is part of the Group’s DNA.