Choosing a Warehouse Management System

The warehouse is an integral part of a business, and it can be a difference-maker when it is powered by the latest technologies.

In the case of a warehouse, what you will need is a Warehouse Management System (WMS), which is basically a software application specifically designed to support and optimise warehouse functionality. Its main goal is to control the movement and storage of materials within the warehouse and assist in the processing of associated transactions, like shipping, receiving, put-away, and picking.

These capabilities will help you stay on top of everything in your warehouse and do it often in one single pane of glass. And this is why it is critical that you choose the right WMS for your warehouse.

So, how exactly should you choose your WMS? What considerations should you keep in mind?

First off, always remember the end goal of warehouse management: To ensure that all activities within a warehouse are well-organised, managed, and maintained so that errors are kept to a minimum—or avoided altogether. That’s because a single error can compromise the speed, efficiency, and productivity of warehouse activity, thus resulting in costly consequences.

An effective WMS, therefore, is meant to minimise errors, and it can only do so if it has the right features and capabilities. These features and capabilities are the ones you will need to keep an eye out for when choosing the WMS for your warehouse.

Here are the most critical:

Keeping Track of and Managing Inventory. A modern WMS keeps tabs on each item in your warehouse to ensure correctly fulfilled orders and accurate inventory counts—all at the click of a button.

Tracking and Improving Customer Service. The right WMS helps you fulfil customer orders quickly, accurately, and efficiently, thus improving customer service.

Real-time Reporting and Analytics. This feature provides insights into warehouse performance through real-time reporting and analytics, helping managers make informed decisions.

Increasing Efficiency in Business Operations. An effective WMS speeds up the process of fulfilling orders while maintaining high standards of quality control and uniformity throughout the warehouse. This enables employees to produce more in less time, thus significantly increasing warehouse efficiency.

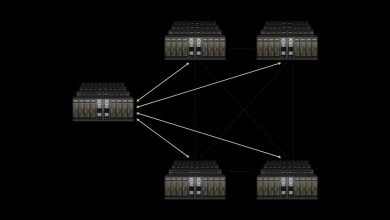

Integrating with Enterprise Resource Planning (ERP). A quality WMS integrates with the management system you already have in place. This allows you to avoid duplicating any processes or procedures already being implemented.

Meeting Regulations for Compliance. A modern WMS helps you meet regulatory requirements through the use of systems that automate corporate operations and enable real-time data capture and tracking.

To be fair, most WMS available today offer these very same capabilities, which leads us to another important consideration: Cost savings. The idea of leveraging innovation is to save money and resources, and that is why you will need to find a WMS that will let you do exactly that.

The AC2’s Wave WMS, which is among the more popular WMS today, ticks all the boxes with its flexibility, integrative capabilities, and award-winning development. It also eliminates the need for purchasing server hardware or software that oftentimes drives costs up needlessly. This makes AC2’s Wave WMS an excellent choice for businesses looking to supercharge their warehouse and make the most out of it.

Additionally, as an advanced solution, AC2’s Wave WMS can automatically upgrade itself at no extra cost, ensuring seamless enhancements to its functionalities. This innovative capability allows you to effortlessly stay ahead of industry trends without requiring significant budget or manpower for frequent system upgrades, offering a cost-effective and future-proof solution.

But while the AC2’s Wave WMS is a sensible choice, choosing the right WMS should be a deliberate, meticulous process where you will have to compare products until you find the one that suits your warehouse the best.