Pusan National University Researchers Identify Key Barriers Hindering MDA

A comprehensive set of issues, covering different aspects of manufacturing data analytics, can help manufacturers transition to smart manufacturing.

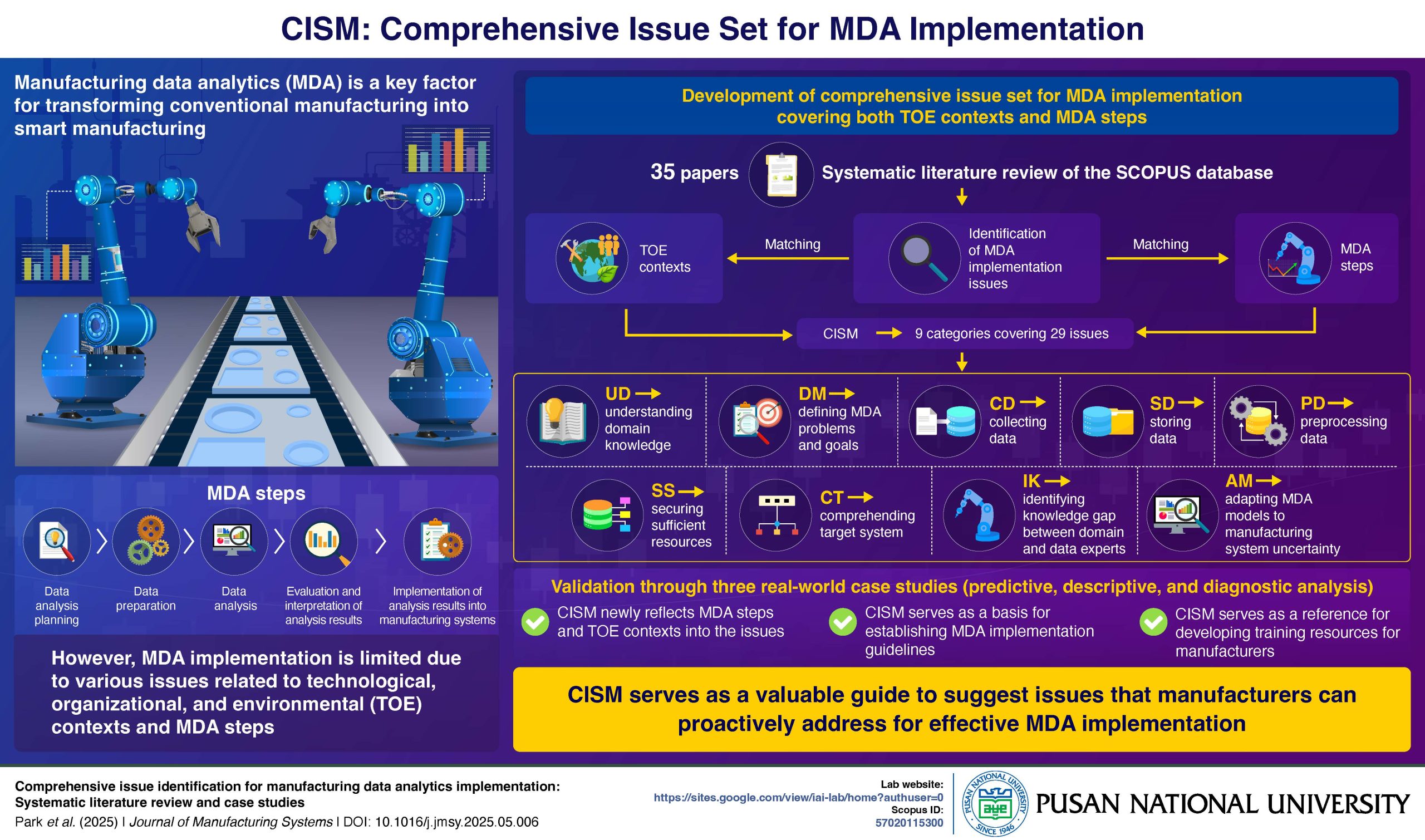

Modern manufacturing requires advanced management methods, and manufacturing data analytics (MDA) has emerged as a key tool to help manufacturers anticipate and respond to rapidly changing conditions. However, despite its clear benefits, MDA adoption remains low due to a variety of challenges. A new study by Pusan National University researchers developed a comprehensive issue set for MDA implementation (CISM) that can help manufacturers proactively identify and resolve these issues, paving the way for broader MDA adoption.

Modern manufacturing operates in complex environments where traditional management approaches are no longer enough. This highlights the need for real-time, dynamic and self-adaptive management strategies. Manufacturing data analytics (MDA) has emerged as a powerful solution for transforming traditional manufacturing into smart manufacturing. Through MDA, manufacturers can identify hidden patterns in external and internal data, allowing them to better anticipate and respond to geopolitical risks and rapidly changing customer expectations and demands. However, despite these benefits, adoption of MDA remains surprisingly low, with fewer than one in five projects reaching full implementation.

Why the Low MDA Uptake?

Because manufacturers face numerous challenges during MDA implementation. The MDA process typically involves four main steps: (1) data preparation, (2) data analysis, (3) evaluation and interpretation of results, and (4)implementation of results into manufacturing systems. Unique issues can arise at each of these steps. Additionally, there are broader issues related to technological, organizational, and environmental (TOE) contexts. While past studies have investigated many of these issues, they have not been able to provide a comprehensive list, overlooking TOE contexts, and being limited to only specific steps of MDA.

To address this gap, a research team led by Assistant Professor Ki-Hun Kim from the Department of Industrial Engineering at Pusan National University, South Korea, developed a comprehensive issue set for MDA implementation (CISM), with active contributions from Sa-Eun Park and Sang-Jae Lee, also from the same department.

“To accelerate the adoption of MDA, manufacturers must first be able to identify and resolve the various challenges that may arise during its implementation. This includes not only technical issues but also organizational and environmental factors that significantly influence the success of MDA initiatives,” explained Dr. Kim. “CISM provides a structured x-framework to proactively recognise and resolve these issues, supporting a more efficient and effective MDA implementation.”

The team included Sa-Eun Park and Sang-Jae Lee, also from Pusan National University. Their study was made available online on 9 June, 2025, and published in Volume 82 of the Journal of Manufacturing Systems in October 2025.

A Systematic Review Gives Way to Eye-Opening Findings

The team first started by identifying relevant literature from the SCOPUS database. They identified 35 papers that addressed various issues related to MDA implementation. By systematically reviewing these papers, they identified a comprehensive set of 29 issues, grouped into 9 categories, each mapped to the relevant TOE context and step of the process involved. Of these, 26 issues are related to technological context, 11 to organisational context, and 4 to environmental context. The 9 categories of CISM reflect different aspects of said process, from understanding the problem and preparing data, to identifying the knowledge gap between data scientists and domain experts, and aligning MDA models to real-world manufacturing systems.

To validate the CISM, the research team applied it to three real-world case studies in the rubber manufacturing industry, focusing on optimising recipe formulation and mixing processes to ensure consistent, high-quality production. The x-framework effectively captured all implementation challenges encountered during the projects, demonstrating its comprehensiveness and practical applicability.

The authors also highlighted directions for future research: ranking the relative importance of each issue, exploring their relevance across different manufacturing contexts, and developing tailored strategies to address them.

“CISM can help manufacturers establish clear guidelines for identifying and prioritising the issues that need to be proactively addressed to ensure effective MDA implementation,” noted Dr. Kim. “Moreover, it can serve as a foundational reference for developing education and training resources related to MDA. These efforts will, in turn, enable manufacturers to deliver high-quality products more efficiently and reliably, extending the benefits directly to consumers.”

In summary, CISM provides a solid foundation for both researchers and practitioners working to improve real-world MDA implementation. It represents a meaningful step forward in the journey toward widespread, data-driven smart manufacturing.